The servo drive system that can be simply engineered for machinery construction

The SINAMICS S210, servo drive system comprises a servo converter and a servomotor – and mainly addresses servo solutions demanding a high dynamic performance in the power range from 50 W up to 7 kW. Engineering this servo drive system is almost effortless. All servo system components are connected using the One Cable Connection. The safety functions for machine safety are already integrated in the SINAMICS S210 servo drive. The connection to the higher-level control is established via PROFINET IRT communication, fast commissioning via the TIA Portal or the integrated web server and One Button Tuning. SINAMICS S210 servo drive – the perfect team comprising a servomotor and a servo converter.

Overview of strengths

Versatile. Precise. Safe.

Main applications of the SINAMICS S210 servo drive system in particular are machines for packaging, handling such as pick & place, wood and ceramics processing, as well as a digital printing and many additional application areas.

Versatile

- SINAMICS S210 is flexible and versatile. They move light loads with a high dynamic performance – and average and large loads very precisely

- In conjunction with the technological functions of the higher-level controller, there are many possibilities of motion

- The SINAMICS S210 converter has an integrated PROFINET IRT (Isochronous Real Time) communications interface for connecting to a control system

Precise

- Low moment of inertia and high overload capability of the motor

- High-resolution encoder with fast scanning

- Short cycle times on the machine are possible even with complex motion control

Safe

- Standard safety concept Safety Integrated. Machine safety for operating and maintenance personnel.

- Integrated safety functions: STO, SBC, SS1-t (time controlled), SS1*, SS2*, SOS*, SLS*, SSM*, SDI*, SLA*, SBT* (*can be optionally activated using a license)

- Seamless implementation of safety functions in accordance with SIL 2 (EN 61508) and PL d (EN ISO 13849-1)

Overview and selection

Selecting your servo drive system step by step

From the ideal servomotor for your application, the optimum servo converter along with suitable cables and connectors up to the right controller for you – we will explain step by step how you get to your servo drive system.

Step 1: The ideal servomotor

Teamed up in a drive system with a SINAMICS S210 servo converter, SIMOTICS S‑1FK2 servomotors provide short control and positioning times, fast and precise control response to disturbances and stable closed-control with a high dynamic performance. Depending on the specific application, two servomotor versions are available:

Advantages

|  |

SIMOTICS S-1FT2 servomotors offer a wide range of different options for the SINAMICS S210 servo system. For example encoders with a high resolution of up to 26 bits improve the system accuracy. A higher degree of protection up to IP67 as well as various motor coatings facilitate the use in harsh environments. In addition, new machine options are available, such as higher rated speeds. Advantages

|  |

SIMOTICS S-1FS2 servomotors complement the motor portfolio for the SINAMICS S210 servo drive system for special applications in the food, beverage and pharmaceutical industries, and plants and systems where standard SIMOTICS S-1FK2 and S-1FT2 servomotors are not sufficient. This stainless steel motor series for operation under strict hygienic conditions is available in three sizes in the power range 0.45 to 2 kW with torques from 3.1 Nm to 14 Nm. Advantages

|  |

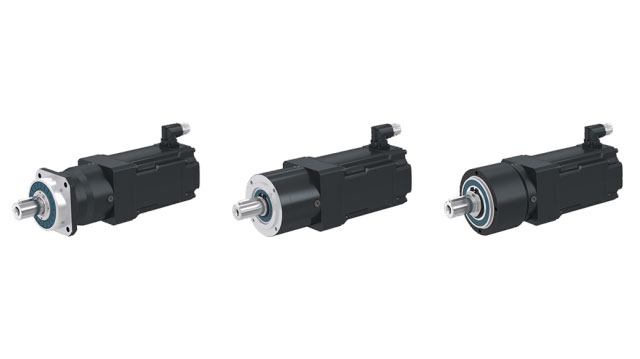

SIMOTICS S-1FK2 servo planetary gearmotors enable the highest cycle rates with a lightweight and low-inertia gearbox design, or inertia adjustment for precise movement of heavy loads. |  |

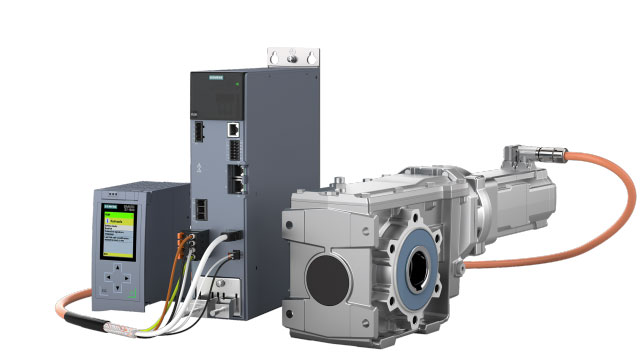

In addition to SIMOTICS S-1FK2 servomotors with planetary gearboxes, the coupling adapter SIMOGEAR KS-Adapter provides an additional flexible solution to connect various SIMOGEAR gearbox units with SIMOTICS servomotors of the SINAMICS S210 servo drive system.

|  |

Step 2: The optimum servo drive

SINAMICS S210 servo converter

The SINAMICS S210 servo drive covers a power range from 0.1 up to 7 kW. In conjunction with a SIMOTICS servomotor from the S-1FK2 or S-1FT2 product series, the system is predominantly designed for discontinuous applications in the machinery construction domain that require a high dynamic performance. SINAMICS S210 fully leverages its strengths when the application involves precise positioning and motion control. Even with the highest dynamic performance, all motion sequences are implemented with the utmost precision. With its outstanding performance, SINAMICS S210 is convincing in packaging machines as well as in handling systems, in woodworking and plastics processing as well as in digital printing.

Step 3: The matching cables

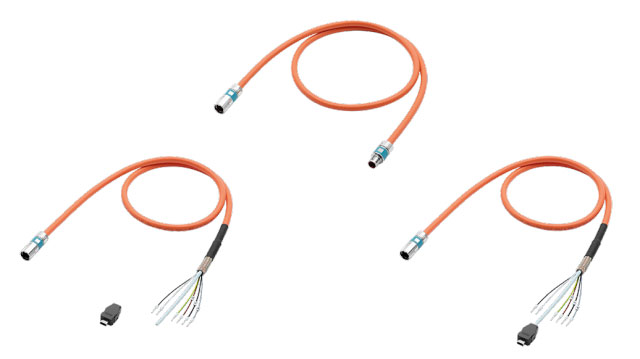

Motor connecting cables – OCC (One Cable Connection)

All motors and frequency converters of the SINAMICS S210 servo system are connected up using just one single cable – this transfers the power, connects an encoder and controls the brake. Simple connection without special tools.

Available cables:

- Motion Connect 500 cables are used for predominantly fixed routing

- Motion Connect 800 cables when routing cables in moving cable carriers (drag chains).

The cables can be ordered prefabricated with the required length.

Prefabricated options

Motor connecting cables – OCC (One Cable Connection)

- Prefabricated OCC motor connecting cable with SPEED-CONNECT plug connector (shield terminal is included in the scope of delivery)

- Prefabricated OCC motor connecting cable with SPEED-CONNECT plug connector with Siemens IX signal connector on the converter side provided separately (shield terminal is included in the scope of delivery)

- Prefabricated extension cable

Step 4: The matching controller

SIMATIC S7-1500 / SIMATIC S7-1500 T-CPU / SIMOTION

In conjunction with the SIMATIC S7-1500 and SIMATIC S7-1500 T-CPU, the SINAMICS S210 servo drive system with PROFINET is an optimally harmonized and coordinated motion control solution in the TIA Portal. Motion control functions – such as positioning, synchronous operation, cams etc. – are implemented using the SIMATIC technology objects available in the SIMATIC S7-1500 control. The appropriate fail-safe SIMATIC variants are available for safety applications. The connection to the SINAMICS S210 servo drive system is made via clock-synchronous PROFINET IRT and the safety connection (in case of faulty Simatic S7 – 1500 F) directly via PROFIsafe.

Totally Integrated Automation

Planning, configuring, engineering and commissioning

The SINAMICS S210 servo drive is integrated in Totally Integrated Automation (TIA) Tools

When it involves selecting and engineering, the SINAMICS S210 servo system is an integral component of Totally Integrated Automation Tools.

The TIA Selection Tool supports you when selecting the optimum motors and drives to address your specific load data and motion profiles. The TIA Selection Tool can be downloaded at no charge as desktop version.

To shorten the engineering time for the complete drive and automation system, the Totally Integrated Automation Portal (TIA Portal) provides a common platform for the overall commissioning and engineering process.

Typical applications

SINAMICS V90

Power range | SINAMICS S210: SIMOTICS S-1FK2 / 1FT2: 1 AC 200 – 240 V / 0,05 kW – 0,75 kW |

|---|---|

Torque range | SIMOTICS S-1FK2 / 1FT2: 1 AC 200 – 240 V / 0,16 Nm – 3,6 Nm |

Communication | PROFINET IRT, PROFIsafe, PROFIenergy |

Safety functions | STO, SBC, SS1-t (time controlled), SS1*, SS2*, SOS*, SLS*, SSM*, SDI*, SLA*, SBT* (* can be optionally activated using a license) |

Commissioning / engineering | Web server / Startdrive |

EMC filter | Integrated (1 AC 230 V: Class C2 / 3 AC 400 V: Class C3); external EMC filters are also available as an option |

Standards | CE, EAC, RCM, KC, cULus |

Motor connection technology | One-cable connection technology (OCC) with SPEED-CONNECT quick-release lock and rotatable, compact connector Permissible cable length: Up to 50 m |

Typical control and motion control functionality | SIMATIC S7-1500 / SIMATIC S7-1500 T-CPU / SIMOTION |

Motor versions | SIMOTICS S-1FK2 See chapter Servo drive overview and selection on this website |

Gears | SIMOTICS S-1FK2 with planetary gearboxes There are three individually adjustable Eco gear variants. SIMOGEAR gearbox SIMOGEAR gearboxes are available with the optional SIMOGEAR KS adapter for servomotors. This offers a flexible solution for combining the motor portfolio of the SINAMICS S210 servo drive system with the SIMOGEAR gear units. For more Details see chapter Servo drive overview and selection on this website |